Infrastructure

Site access road

Work on the Bougouni site access road commenced at the end of 2023 and was completed by local Malian contractors in March 2024.

Long lead items

In March 2024, the Bougouni Project team, headed up by Jerry Gao and Steve Zaninovich, signed contracts for the purchase of the two main long lead equipment packages: the crushing circuit and the DMS processing equipment.

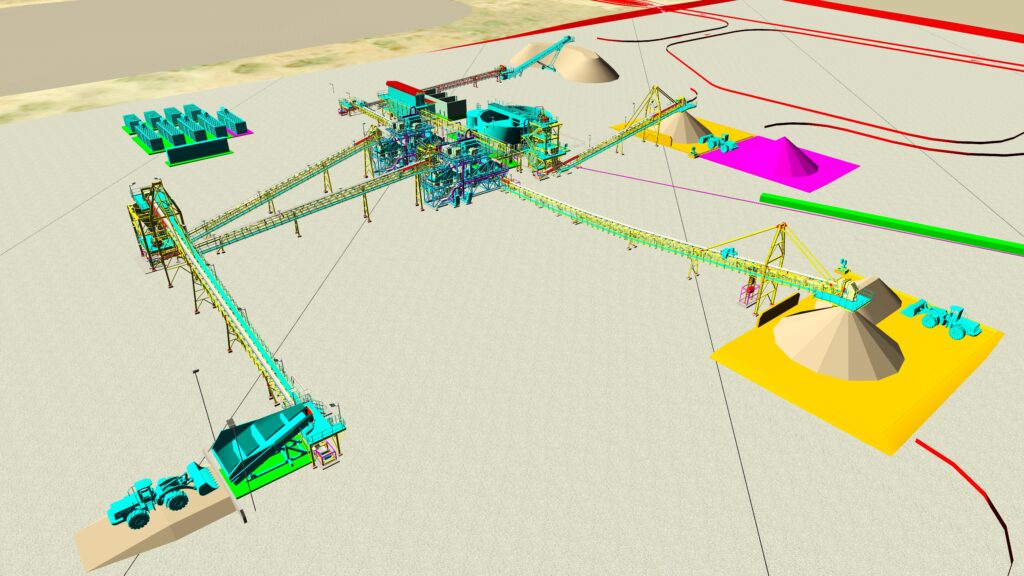

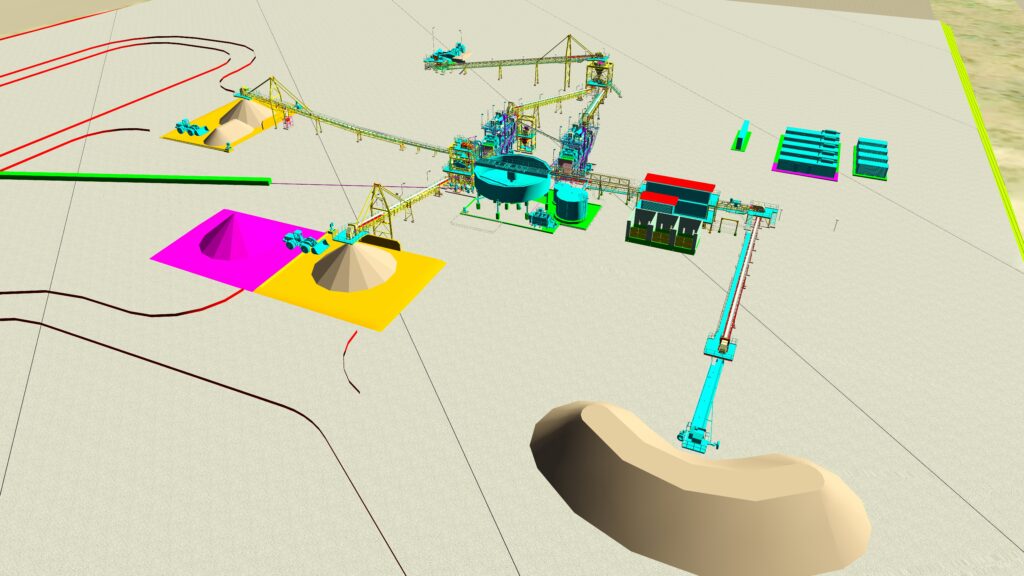

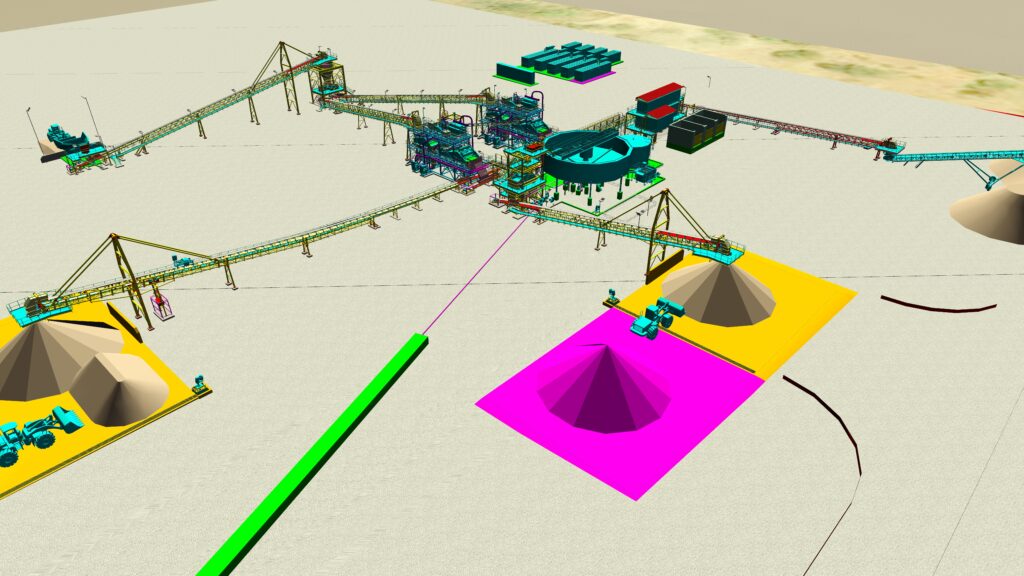

Crushing Modules

The dual crushing circuit modules contract will be supplied by Beijing High Dynamic Technology Co., Ltd. (BHD), a well recognised supplier of crushing equipment of similar and much larger capacity to numerous projects in China and worldwide. BHD will provide a turnkey design and supply package for the dual crushing equipment modules, including all ancillary equipment, in accordance with the detailed design concept established with DRA Projects in South Africa.

DMS Processing Plant Equipment

The DMS equipment will be supplied by Haiwang Technology Group (Haiwang). The scope of work includes the provision of final detailed design services to provide a fully integrated DMS processing plant, the supply of all processing equipment required for the DMS operation, and the associated electrical, instrumentation and process controls.

Haiwang’s equipment will provide a superior performance guarantee for the DMS plant based on exceeding Kodal’s throughput target and achieving concentrate grade above Kodal’s Company’s 5.5% target for the production of 125,000 – 130,000 tonnes per annum of spodumene.

The Haiwang DMS plant throughput guarantee is based on achieving 4,848 tonnes per day of ore feed over a continuous seven-day period.

This translates to an annualised throughput rate of 1.2 million tonnes per annum (after allowances for routine maintenance and downtime), which provides the Company with major potential production upside.

Haiwang is a leading provider of classifying equipment with a focus on cyclone separation, a key factor in DMS processing. In the past 10 years, Haiwang has supplied DMS equipment of similar capacity to numerous DMS projects worldwide, including China, Namibia and Zimbabwe.

Haiwang’s equipment will provide a superior performance guarantee for the DMS plant based on exceeding Kodal’s throughput target and achieving concentrate grade above Kodal’s Company’s 5.5% target for the production of 125,000 – 130,000 tonnes per annum of spodumene.

The Haiwang DMS plant throughput guarantee is based on achieving 4,848 tonnes per day of ore feed over a continuous seven-day period.

This translates to an annualised throughput rate of 1.2 million tonnes per annum (after allowances for routine maintenance and downtime), which provides the Company with major potential production upside.

Haiwang is a leading provider of classifying equipment with a focus on cyclone separation, a key factor in DMS processing. In the past 10 years, Haiwang has supplied DMS equipment of similar capacity to numerous DMS projects worldwide, including China, Namibia and Zimbabwe.

Haiwang’s equipment will provide a superior performance guarantee for the DMS plant based on exceeding Kodal’s throughput target and achieving concentrate grade above Kodal’s Company’s 5.5% target for the production of 125,000 – 130,000 tonnes per annum of spodumene.

The Haiwang DMS plant throughput guarantee is based on achieving 4,848 tonnes per day of ore feed over a continuous seven-day period.

This translates to an annualised throughput rate of 1.2 million tonnes per annum (after allowances for routine maintenance and downtime), which provides the Company with major potential production upside.

Haiwang is a leading provider of classifying equipment with a focus on cyclone separation, a key factor in DMS processing. In the past 10 years, Haiwang has supplied DMS equipment of similar capacity to numerous DMS projects worldwide, including China, Namibia and Zimbabwe.